Manufacturing a Die

A good die sinker must be an all-round mechanic. The pattern is first lightly stamped with die-sinkers’ chisels to get the outline. The rest of the work consists of scraping, gouging and chiselling the final design. The die sinker is often an artist and has the ability to do delicate handwork.

When the engraving is finished, the die is heated and suddenly cooled to harden it. In hardening the dies, only the ‘face’ (the top half of the die where the pattern is inscribed) is hardened. The surface is then polished by ‘lapping’ – a process in which two surfaces are rubbed together with an abrasive between them, by hand movement or using a machine. The die is then ready for use in the stamp.

360 View of a Die Block

Use the play button to rotate the object automatically, or alternatively you can drag the item with the mouse or your finger to move it around.

This item is in the following Themes:

Steel, cast into blocks, is not suitable for drop-forging dies, as flaws are likely to develop, so as a general rule, forged blocks of open-hearth crucible steel are used. These blocks are often purchased ready. A rough estimate of the average life span of a die is four-thousand pieces or ‘blows’. Some dies might be broken immediately, while others may last for a 100,000 pieces or more. The blocks are always made oversized so that enough of the surface can be machined off to ensure good sound metal to work on.

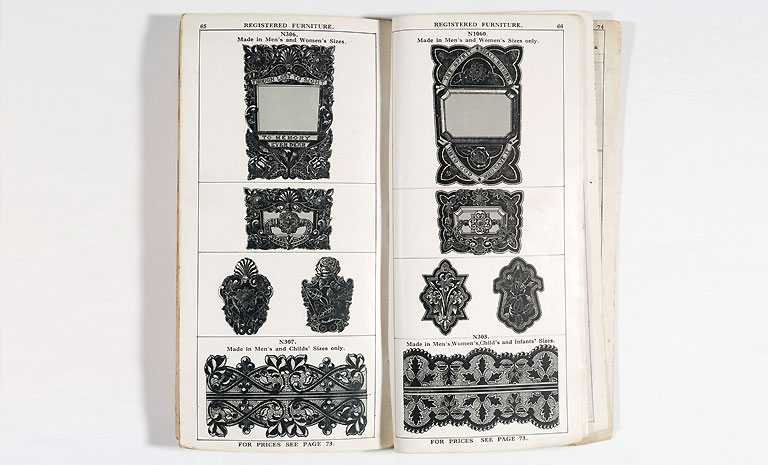

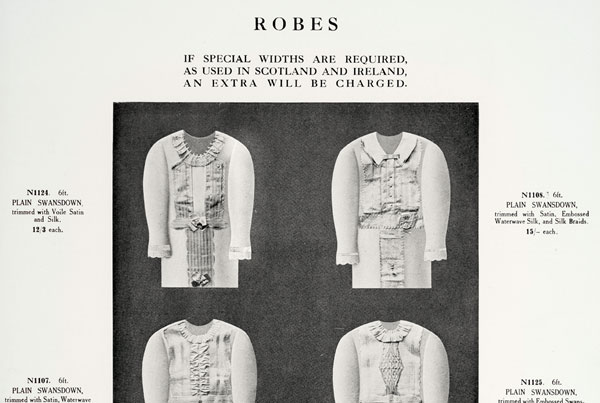

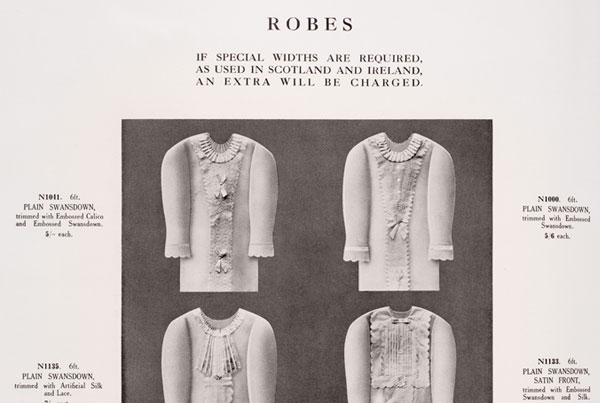

The Jewellery Quarter as the centre of Britain’s coffin furniture trade

The area now known as the Jewellery Quarter became a popular location for metalworking trades; a lack of restrictions on the building of small workshops in the gardens of houses on the Newhall Estate meant that small businesses could be set up with little capital outlay. The concentration of trade in the area was further consolidated by increasing specialisation and sub-division of process in the metalworking industries, which forced the localisation of increasingly inter-connected businesses. By the mid-nineteenth century, the area had become a dense and vibrant industrial village in the heart of the city in which masters, workers and their families both lived and worked.

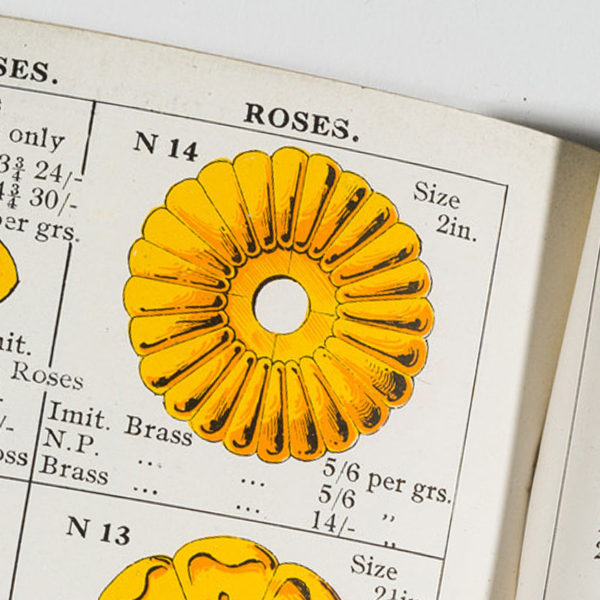

The area’s main industry was obviously the manufacture of jewellery, though this was by no means the quarter’s only trade, as the skills and processes required to make jewellery were applicable to many other metalworking industries. The coffin furniture trade itself had arrived in the area as early as 1760, when enterprising Birmingham tradesmen began to compete with the Southwark firms who had previously dominated the industry. They offered cheaper prices and an ability to adapt to new technologies and changing consumer demands; the 1769 invention of Pickering’s stamp press made mass-production easier, whilst the emergence of dies at the end of the eighteenth century brought further simplification and savings in cost of up to 80%.

The perfection of die-sinking in the early 1800s improved the quality and variety of designs, essential to compete in the massively regionally and socially variable coffin furniture market. The Jewellery Quarter became known as a source of high quality goods; its matte black “japanned” coffin fittings (silver dipped tin painted with a thick black lacquer) were the height of fashion for upper class Victorian funerals.